Apple, Walmart, Amazon, Uber, Microsoft, Zara, Toyota et General Motors… implement it already! Let ’s learn a little more through these following lines this little popularized concept which is the Supply Chain Maverick.

This is not a new notion as it as first uttered in 2001 by Professor Constantine Kontocosta of de New York University.

But Professor Michael Porter had already laid the groundwork in 1985 in «Competitive Advantage: Creating and Sustaining Superior Performance».

Professor Constantine has used it to describe supply chains managed in an unconventional way. His motto : reinvent the supply chain !

By using the term Maverick, he wanted to pay tribute to the famous Texas breeder Samuel Augustus Maverick, known for his innovative and unconventional approach to managing his estate. He multiplied his earnings many times over by taking risks and implementing uncommon strategies.

The Maverick Supply Chain is a more flexible and scalable structure that enables supply chains to adapt more quickly and efficiently to market changes through the adoption of modern technologies and the development of standard processes.

Improving visibility between suppliers and retailers, improving ordering, payment, and delivery processes, and providing greater flexibility in the supply chain are just some of the objectives of the Maverick supply chain.

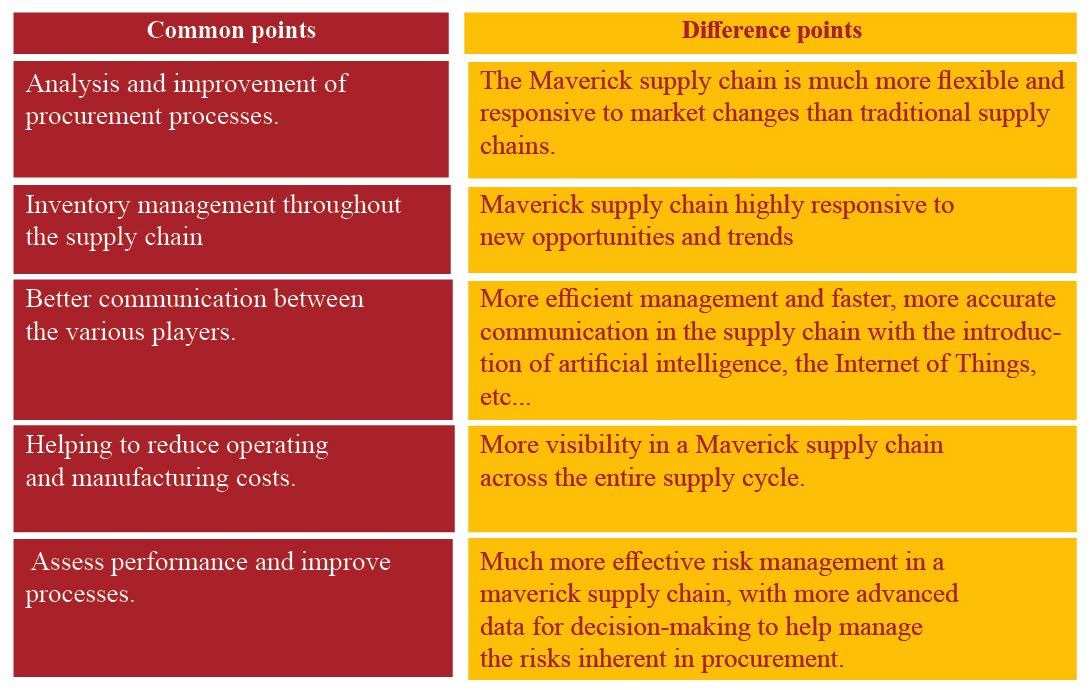

At this point, it’s tempting to ask what’s the difference between a «classic» supply chain and a Maverick supply chain?

The following table shows the major similarities and differences between the 2 concepts.

By its very nature, the implementation of a Maverick supply chain presents certain challenges:

- Flexibility: involves efforts to monitor and manage the complexity of flows, which can be very restrictive.

- Complexity: These multiple pathways with numerous suppliers, sales outlets and technical platforms can quickly spill over when integrating new business partners.

- Resource organization: the independence and non-centralization of the Maverick supply chain can make it difficult to coordinate resources. New suppliers, emerging markets, knowledge of risk response and compliance are factors that can complicate the implementation of such a supply chain.

- Risks: Maverick supply chain risks are greater because there are more ways for the supply chain to break down. Companies need to seize the opportunity to diversify their supply chain, and at the same time balance their risks while trying to keep costs down.

To resolve these difficulties, companies can look to improve their processes and technologies… read more in our latest magazine

By Jean Noel N’GOUAN, CMILT